What do the safest, most efficient fleets have in common? Why are the most respected names in trucking, safety, and environmental regulation endorsing the most advanced tire health technologies? And perhaps most importantly, what does that mean for fleets that haven’t yet made the switch?

Tire pressure management systems are no longer experimental or niche. Automatic Tire Inflation Systems (ATIS) and Tire Pressure Monitoring Systems (TPMS) are trusted, standardized tools used across high-performing fleets. These systems are not just backed by anecdotal success—they’re vetted by federal agencies, safety alliances, environmental authorities, and top industry groups based on extensive real-world testing and validated performance.

If you’re still viewing these technologies as “nice to have,” it’s time to reframe your thinking. The data is in; the case is clear; and the endorsements are strong: ATIS and TPMS are the standard for smart fleet operations.

Here’s a closer look at who’s validating these technologies—and why their support matters.

1. Commercial Vehicle Safety Alliance (CVSA)

In the CVSA’s 2024 roadcheck, tires ranked number two amongst out-of-service vehicle violations in the United States as well as North America. In addition, the CVSA updated its North American Standard Out-of-Service Criteria in 2024 (Part 11, Item 12) to acknowledge that tires actively being inflated by an automatic system no longer warrant out-of-service designation, even if they’re momentarily underinflated. The CVSA made this change, validating that ATIS systems like the Halo Tire Inflator allow a truck with a compromised tire to pull off to a safe place for repairs. This saves the driver and technician from an otherwise dangerous roadside repair. This ruling reinforces the effectiveness of ATIS for over-the-road operations.

What it means: The CVSA recognizes that underinflated tires are more likely to experience a safety issue, leading to dangerous situations on the road. ATIS systems are trusted enough to influence safety enforcement policy across North America.

2. Federal Motor Carrier Safety Administration (FMCSA)

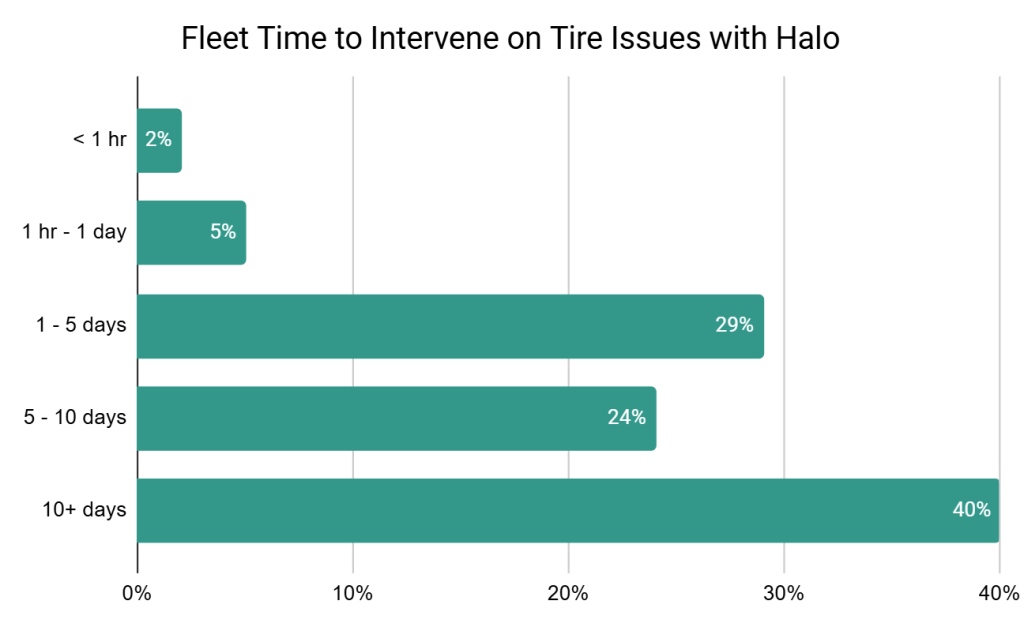

The FMCSA has invested in research analyzing how ATIS and TPMS reduce crash risk and maintenance costs. These findings consistently point to improved tire health, fewer roadside breakdowns, and enhanced operational safety. The FMCSA presented Aperia’s data from over 30,000 tires at a safety session in 2024, highlighting chronic underinflation as the real cause of flat tires. Using real-world fleet data, Aperia proved that with Halo ATIS and predictive analytics technology, fleets have ample time to resolve tire issues and avoid ERS calls. The data shows that 98% of flat tires* do not occur spontaneously, but rather due to chronic underinflation; after all. Halo ATIS maintains optimal pressure, counteracts leaks, and eliminates the chronic underinflation that causes most tire incidents. Halo then informs the fleet of the remaining tire issues early, allowing ample time to intervene and avoid an ERS call. The chart below demonstrates that with Halo, fleets have an entire day or more to intervene on 93% of all tire issues.

What’s more, fleets have over ten days to intervene on 40% of all tire issues regardless of severity. Only a minuscule 2% of tire incidents require immediate intervention (less than an hour) before failure. Even most critical issues, if detected early with Halo, can be identified and addressed in plenty of time. This is great news for fleets.

*Flat tires are defined as 50 psi or lower.

What it means: Most tire problems result from chronic underinflation or slow leaks—conditions that Halo Tire Management technology solves by maintaining optimal pressure and flagging exceptions early. By equipping fleets with ample time to act on 93% of issues before they become urgent, advanced tire management like Halo turns an unpredictable, high-risk maintenance headache into a planned, controllable service event.

3. National Highway Traffic Safety Administration (NHTSA)

NHTSA mandates Tire Pressure Monitoring Systems (TPMS) in all passenger vehicles and continues to emphasize tire pressure as a critical safety factor. While TPMS is not yet required for heavy-duty trucks, this foundational support underscores its safety-enhancing value across vehicle types and sets the stage for broader adoption in commercial fleets.

Beyond safety, NHTSA, together with the U.S. Environmental Protection Agency (EPA), sets national fuel consumption and greenhouse gas (GHG) standards for medium- and heavy-duty vehicles—including Class 8 trucks—through the U.S. Heavy-Duty National Program. NHTSA defines the fuel consumption targets while the EPA establishes the CO₂ emissions limits, creating a coordinated regulatory framework that manufacturers and fleets must meet. EPA and NHTSA Phase 2 rulemaking documents cite an approximate 1% fuel savings for every 10 psi of inflation maintained, a widely used figure in industry and government modeling. This is the basis for ATIS credit in the rules.

A key reason these standards exist is that underinflated tires increase rolling resistance, making engines work harder and burn more fuel. To address this, federal rules explicitly recognize ATIS as an approved compliance technology. By automatically maintaining proper tire pressure, ATIS reduces rolling resistance, improves fuel economy, and lowers emissions; benefits that are factored directly into meeting federal fuel efficiency and GHG targets.

What it means: TPMS is already an accepted safety standard in light-duty transportation, and adoption in heavy-duty fleets is building on that precedent. ATIS technology isn’t just operationally effective; it’s officially credited by the highest U.S. transportation authority as a practical, measurable way to improve fuel efficiency and support compliance with national standards.

4. U.S. Environmental Protection Agency

As mentioned above in 2022, the EPA formally authorized OEMs to install the Halo Tire Inflator—a leading ATIS solution—on new medium- and heavy-duty tractors as a recognized strategy to meet Greenhouse Gas Phase 2 standards. This green light reflects the system’s measurable impact on reducing emissions and improving fuel efficiency. In addition, the EPA awarded Aperia with the Clean Air Excellence Award in 2020 for Halo’s ability to “reduce pollutant emissions, demonstrate innovation, offer sustainable outcomes, and provide a model for others to follow.”

What it means: ATIS technology isn’t just operationally effective, it’s officially recognized as an emissions-reducing tool by the highest environmental authority in the United States.

5. American Trucking Associations (ATA)

The ATA has spotlighted tire pressure technology in numerous whitepapers and conference sessions, including in recent research from ATRI, which outlines tire and fuel efficiency gains from inflation systems. Top-performing fleets within the ATA membership routinely spec ATIS and TPMS across their assets.

What it means: The best fleets in the country aren’t experimenting, they’re already relying on these systems to deliver results.

6. ATA’s Technology & Maintenance Council (TMC)

TMC, has issued official Recommended Practices (RPs) dedicated to ATIS and TPMS. More specifically:

- RP 271: Integration of Tire Pressure Monitoring Systems (TPMS) or Automatic Tire Inflation Systems (ATIS) with Vehicle Telematics,

- RP 239B: Commercial Vehicle Tire Inflation And/Or Monitoring System Guidelines

These technical guides are developed with deep input from fleet maintenance experts and OEMs and set the standard for spec’ing and sustaining these systems effectively.

What it means: ATIS and TPMS are embedded in the industry’s technical playbook; this is best-practice maintenance, not a trial run.

7. North American Council for Freight Efficiency (NACFE)

In its Confidence Reports, NACFE has highlighted the cost savings and performance improvements of tire pressure systems, calling them “high-confidence” technologies based on long-term field data from real-world fleet use.

What it means: Independent validation shows these technologies deliver consistent, measurable returns over time.

Final Word: Proven, Not Emerging

ATIS and TPMS are not “emerging” technologies. They’re proven solutions backed by the most trusted voices in transportation, safety, and sustainability. Top fleets trust them, respected organizations stand behind them, and the results speak for themselves.

If your fleet isn’t already leveraging tire pressure automation, the question isn’t whether you should adopt—it’s what are you waiting for.

Halo Connect i3™: Raising the Bar for Tire Management

For fleets ready to take tire health even further, Halo Connect i3 sets a new industry benchmark. It’s the only system on the market that seamlessly combines automatic tire inflation with predictive analytics, enabling fleets to transition from reactive maintenance to proactive tire health management. What sets i3 apart is its dynamic control capabilities, including remote setpoint adjustment, giving fleet managers unprecedented control over tire pressure in real time, from anywhere.

Whether your goal is to reduce tire ERS incidents and CVSA violations, extend tire life, or improve fuel efficiency, Halo Connect i3 is the most advanced and intelligent tire management solution available today. Learn more about Halo Connect i3 here.

Sources:

U.S. EPA/NHTSA, “Greenhouse Gas Emissions and Fuel Efficiency Standards for Medium- and Heavy-Duty Engines and Vehicles—Phase 2 Regulatory Impact Analysis,” EPA-420-R-16-900, August 2016.

https://cvsa.org/news/2024-roadcheck-results/

https://cvsa.org/news/2024-oosc/

https://www.epa.gov/newsreleases/epa-honors-clean-air-projects-17th-year